You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I bet some of you know what these 2 PITAs are...

- Thread starter jrrjr71

- Start date

jrrjr71

Member

I'll have to look into what's involved, but thanks for the suggestion CT.

I just started off wanting to check the stator/points/condenser. Then I find an oil leak at the bottom of stator plate. Then the stator plate screws rear their ugly heads and turn into a 90-minute removal process. Now CT notices i'm probably losing some oil pressure do to my fairly worn pump sprocket. Isn't it funny how a seemingly simple maintenance can turn into a whole bunch of stuff you hadn't planned on doing?

Seriously though, i'm still trying to ascertain what needs to be done on this new-to-me 78. i'd like to do as little as possible and get out riding. Then do a complete rebuild this winter.

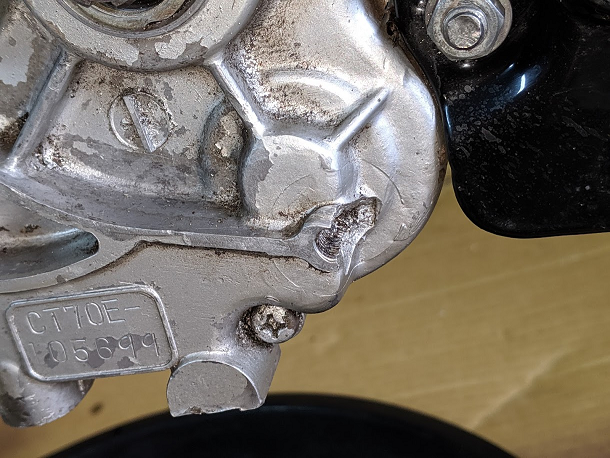

Oh, I also found this under the crank cover today:

Anyone ever try and weld an aluminum M6 threaded sleeve to a case before? Since it's just for the cover/chain guard, maybe that'd work?

I just started off wanting to check the stator/points/condenser. Then I find an oil leak at the bottom of stator plate. Then the stator plate screws rear their ugly heads and turn into a 90-minute removal process. Now CT notices i'm probably losing some oil pressure do to my fairly worn pump sprocket. Isn't it funny how a seemingly simple maintenance can turn into a whole bunch of stuff you hadn't planned on doing?

Seriously though, i'm still trying to ascertain what needs to be done on this new-to-me 78. i'd like to do as little as possible and get out riding. Then do a complete rebuild this winter.

Oh, I also found this under the crank cover today:

Anyone ever try and weld an aluminum M6 threaded sleeve to a case before? Since it's just for the cover/chain guard, maybe that'd work?

OLD CT

Well-Known Member

The best time to fix the case would be when you split the cases. It can be fixed by a good tig welder. Someone painted the cases already so the paint needs to be removed before welding. Vapor blasting the cases before you fix em. Replacing the oil pump and timing set is easier than you think. Heck, you just mastered the stator plate removal. Way harder than doing the timing set.. Just buy OEM Honda replacement parts. Not the aftermarket cheap China crap or the all in one kits. It's cheap for a reason. Because it won't last.

A new timing set is GREAT piece of mind..

A new timing set is GREAT piece of mind..

Last edited:

You're making your life more difficult than it has to be. There's a single step which, once done, will make the rest of the engine work a breeze...splitting the cases. X2 on what Adam posted. WTF is a ziptie doing inside the crankcase and what other surprises might be lurking?

Going through the oil pump, i.e. checking for binding, then removing the cover to inspect the gerotor assembly is a 5-minute job, if you work slowly. The timing chain assembly (chain, tensioner piston cap, idler, roller) should be replaced at this point, anyway.

Once the cases have been split, you'll then be able to inspect the internals, clean the case halves and have that missing aluminum replaced, the hole redrilled & tapped.

I'd go in expecting to find worn shift forks; those are easily replaced. I'd also want to inspect the crankshaft assembly, to be sure that the rod is not worn beyond service limits, at either end. Wet blasting, a.k.a. "vapor honing", can only be done on bare case halves. In some instances, it is the best option but those are a small percentage...imho. I'm not a fan of that process for CT70 engine cases as it changes the as-cast surface, permanently. Dry blasting, using walnut shells, is the preferred cleaning method; they're softer than metal, will take the paint off and not affect the surface. Any staining left behind can then be cleaned with aluminum prep, or sodium hydroxide (found in most oven cleaning products) and a nylon bristle brush...then rinsed with water. If there are stubborn stains, from deep pitting, that refuse to cooperate, then wet blasting would be the best option...but...only if the discoloration is in visible areas with the engine installed.

As for the case repair, once the casting has been cleaned, it's fairly straightforward. I'd prepare that spot by carefully glass bead blasting, keeping that tightly localized to just where the weld bead will go. Follow that with solvent cleaning (brake parts cleaner) and the welder will have a good surface that won't contaminate the weld. Contrary to popular assumption, heliarc welding heat, of aluminum, will be localized. A pro (and this is strictly a professional repair) will have no trouble laying down a nice bead of aluminum, leaving just enough of the intact side of the threaded hole to allow you to reestablish it. After the welding, the surface gets milled flat (ideally) or, if you're skilled enough, filed flat. The hole then gets redrilled on a press. A machine shop can do this, using a Bridgeport. Figure $35-45 for each repair (the welding and machining). The repaired case half can then be metalfinshed, if you wish; it's not a visible location, once the chainguard is in place. That's it...properly repaired and still the original case half with its SN intact.

What you might not realize, yet, is just how little time all of this really requires. An engine rebuild is roughly a daylong (~8 man hours) process, most of which is spent cleaning. The teardown & reassembly, together, comprise less than half of the total work time. Might need a week, or two, to source all of the parts and get the farmed-out work done, then it's down to a full day's work...to get the thing done right, back to mechanically-new, ready for the next 4 decades...and you won't have to go back into the motor, after hoping it will be okay for this season.

Going through the oil pump, i.e. checking for binding, then removing the cover to inspect the gerotor assembly is a 5-minute job, if you work slowly. The timing chain assembly (chain, tensioner piston cap, idler, roller) should be replaced at this point, anyway.

Once the cases have been split, you'll then be able to inspect the internals, clean the case halves and have that missing aluminum replaced, the hole redrilled & tapped.

I'd go in expecting to find worn shift forks; those are easily replaced. I'd also want to inspect the crankshaft assembly, to be sure that the rod is not worn beyond service limits, at either end. Wet blasting, a.k.a. "vapor honing", can only be done on bare case halves. In some instances, it is the best option but those are a small percentage...imho. I'm not a fan of that process for CT70 engine cases as it changes the as-cast surface, permanently. Dry blasting, using walnut shells, is the preferred cleaning method; they're softer than metal, will take the paint off and not affect the surface. Any staining left behind can then be cleaned with aluminum prep, or sodium hydroxide (found in most oven cleaning products) and a nylon bristle brush...then rinsed with water. If there are stubborn stains, from deep pitting, that refuse to cooperate, then wet blasting would be the best option...but...only if the discoloration is in visible areas with the engine installed.

As for the case repair, once the casting has been cleaned, it's fairly straightforward. I'd prepare that spot by carefully glass bead blasting, keeping that tightly localized to just where the weld bead will go. Follow that with solvent cleaning (brake parts cleaner) and the welder will have a good surface that won't contaminate the weld. Contrary to popular assumption, heliarc welding heat, of aluminum, will be localized. A pro (and this is strictly a professional repair) will have no trouble laying down a nice bead of aluminum, leaving just enough of the intact side of the threaded hole to allow you to reestablish it. After the welding, the surface gets milled flat (ideally) or, if you're skilled enough, filed flat. The hole then gets redrilled on a press. A machine shop can do this, using a Bridgeport. Figure $35-45 for each repair (the welding and machining). The repaired case half can then be metalfinshed, if you wish; it's not a visible location, once the chainguard is in place. That's it...properly repaired and still the original case half with its SN intact.

What you might not realize, yet, is just how little time all of this really requires. An engine rebuild is roughly a daylong (~8 man hours) process, most of which is spent cleaning. The teardown & reassembly, together, comprise less than half of the total work time. Might need a week, or two, to source all of the parts and get the farmed-out work done, then it's down to a full day's work...to get the thing done right, back to mechanically-new, ready for the next 4 decades...and you won't have to go back into the motor, after hoping it will be okay for this season.

jrrjr71

Member

Thanks for all the good info racerX, i'm putting together a parts list. Should I replace the stock oil pump with the high volume unit since I'm in there anyways?

I've also decided to "update" the stator plate screws with these stainless allen flat heads($9), the middle one is 16mm :

https://www.amazon.com/gp/product/B07RKKJGNF/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

I've also decided to "update" the stator plate screws with these stainless allen flat heads($9), the middle one is 16mm :

https://www.amazon.com/gp/product/B07RKKJGNF/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

OLD CT

Well-Known Member

Well if it is a black 1978 frame, no need to put a lot of money into repairing the case... It's not the original engine. You have a engine from a 1969 KO silver tag. #105699. You can buy whatever left side case you want. Things just did get a little more difficult, Racer.

#105699. You can buy whatever left side case you want. Things just did get a little more difficult, Racer.

Last edited:

Adam-NLV

Well-Known Member

If that engine is all silver tag original, you should be happy. The ST parts are quite valuable especially the engine.If you have a silver tag head with the |||◇ on it i would be interested. I need a silver tag head.

I had some ST parts and did have a real ST head but needed a helicoil on the spark plug threads. Someone made me an offer on it that i didn't refuse.

Didn't see the SN on this tiny screen...and, yeah, that changes everything. Only time it's worthwhile repairing a case half is when it's original to the bike and that only applies to the LH side; the RH halves are all the same, until the GB4 versions (12v/needle tranny bearings) arrived....years after 1978. Mo`better to sell a ST engine to a hardcore purist-collector and rebuild a K1-79, which will also have the correct primary drive ratio, the one that pairs with 15/35 sprockets of the K1-later bikes. Who knows, might even find a `78, though that's a longshot.Well if it is a black 1978 frame, no need to put a lot of money into repairing the case... It's not the original engine. You have a engine from a 1969 KO silver tag.#105699. You can buy whatever left side case you want. Things just did get a little more difficult, Racer.