kirrbby

Well-Known Member

This thread is to give me a place to post up info about the various stators that we find on little Honda's.

Please contribute to this thread if you have good info, or questions, or anything to add.

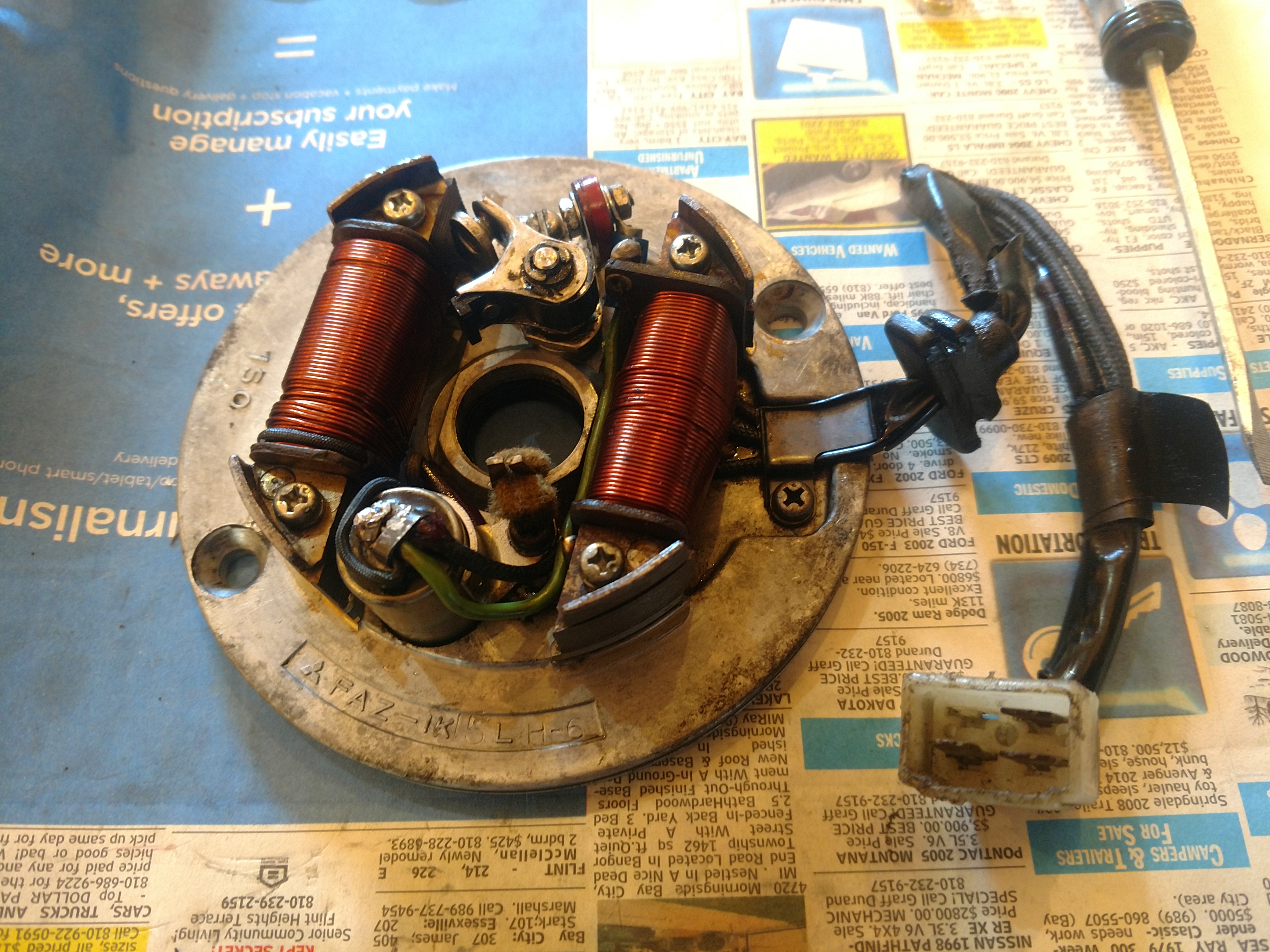

First up is a 3 wire Mitsubishi stator from a CT70 HK0.

It looks pretty good, except someone replaced the points wire with a generic green, with a loop, instead of the stock open ended connector on a black wire.

Removed from the plate.

You can see the end of the yellow wire comes out of the center area of the winding. So I'm saying that it is one of the TWO "center tap"s that come out of the lighting coil.

Please contribute to this thread if you have good info, or questions, or anything to add.

First up is a 3 wire Mitsubishi stator from a CT70 HK0.

It looks pretty good, except someone replaced the points wire with a generic green, with a loop, instead of the stock open ended connector on a black wire.

Removed from the plate.

You can see the end of the yellow wire comes out of the center area of the winding. So I'm saying that it is one of the TWO "center tap"s that come out of the lighting coil.