Thanks kirrbby, I know that's a tall order. The worst case, I can always order 2 or 3 10 packs of 6 x 12 bolts from CHP and hopefully get 14 good ones and if I actually get 20 or 30 good ones then I could give the extra to whoever needs them. I don't have any of my 6 x 12 because I had the brilliant idea that if I bagged and labeled each different group of bolts by size and length that would help ensure that no bolts would be unaccounted for, well that didn't work. I'm guessing that bag must of somehow been misplaced at the plater. On a good note this bag of bolts were the only items that did not make the return trip from the plater. The 6 x 20 bolts I canned because they looked like crap even more so after plating.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zinc Plating

- Thread starter Buddy

- Start date

scrubus

Member

Getting ready to send a batch of hardware to Parker Metal Finishing in Greensboro North Carolina for clear zinc plating. Does anybody have any "8" Hex bolts 6 x12 and 6 x 20 available for sale.

I re-plated my old ones after I wire wheeled them clean. You can get zinc plating kits relatively cheap. Re-plate and buff them out, they'll look great.

JHminitrails

Well-Known Member

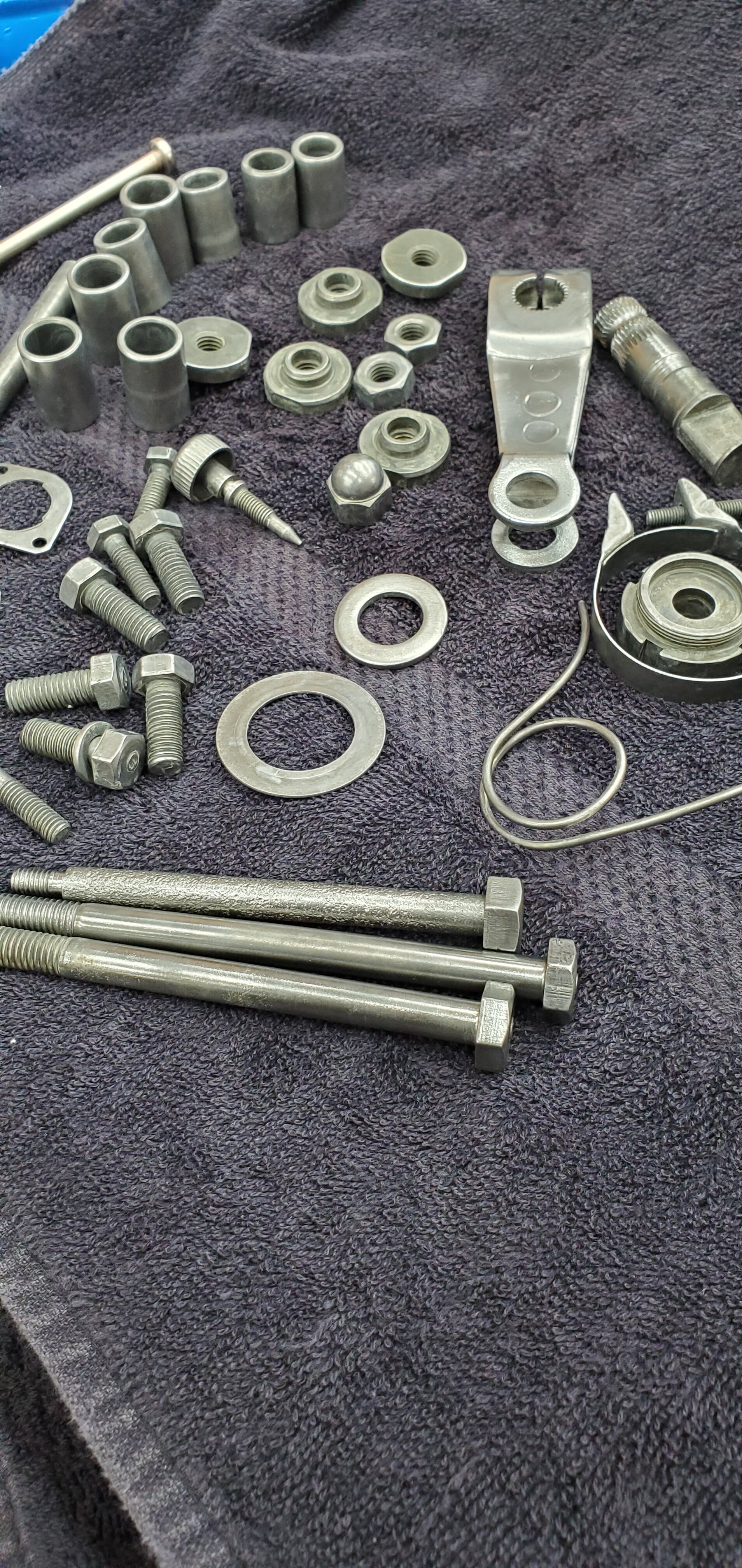

I've had 3 batches of hardware replated now. Which the first 2 have all turned out good, but I still wasn't happy with the dull luster of the plating. I did zero prep on the first 2 batches of hardware and left it up to the plating shop thinking they chemically stripped all the parts beforehand. Turns out they don't, they sandblast them. The results were OK, but I was determined to get a better quality zinc finish on my next batch of parts. So I purchased a 5lb vibratory tumbler. After some experimenting with medias and solutions, my final recipe was green tumbling pyramids from Amazon and a 50/50 mixture of CLR and water. The secret is just that....the pyramids only work best wet with a solution. After tumbling the parts for 18-20 hours, they came out damn near spotless and in raw steel finish. I had to doctor up a few spots with the wire wheel, but this method sure was easy. And the zinc results paid dividends for sure! As the pics speak for themselves. I spoke to the owner of the plating shop and he simply said, the zinc quality and finish is only as good as the metal it's going on! And after seeing my 3rd batch of parts, I strongly agree. Some people may be against the tumbling method because it's a time thing, but for me, I do the hardware tumbling first thing after teardown, fire it in the machine, and carry on doing other work while the tumbler shakes away in the corner! Pretty happy with it.

After Tumbling...

After Zinc Plating. The seat latch pictured was not tumbled or prepped before plating, and the difference is significant.

After Tumbling...

After Zinc Plating. The seat latch pictured was not tumbled or prepped before plating, and the difference is significant.

JHminitrails

Well-Known Member

That stuff looks awesome! Thanks for posting about this.

Thanks. Probably over restored zinc quality for a 100 point period correct restoration. From what I've learned doing this work is that in the 70's the plating was cadmium which I think has a more dull appearance. Regardless, these bolts and parts are going to make a huge difference on my restoration.

JHminitrails

Well-Known Member

From what I've learned, read and been told by the "good ol' boys" and the owner of the plating shop I go to here, they say Cad. But I was not a tech or even born in the 70's so I can only go by what I've learned on my ownSo just so I'm straight - cad is factory not zinc ? I thought it was zinc - but I'm a newb

Gary

Well-Known Member

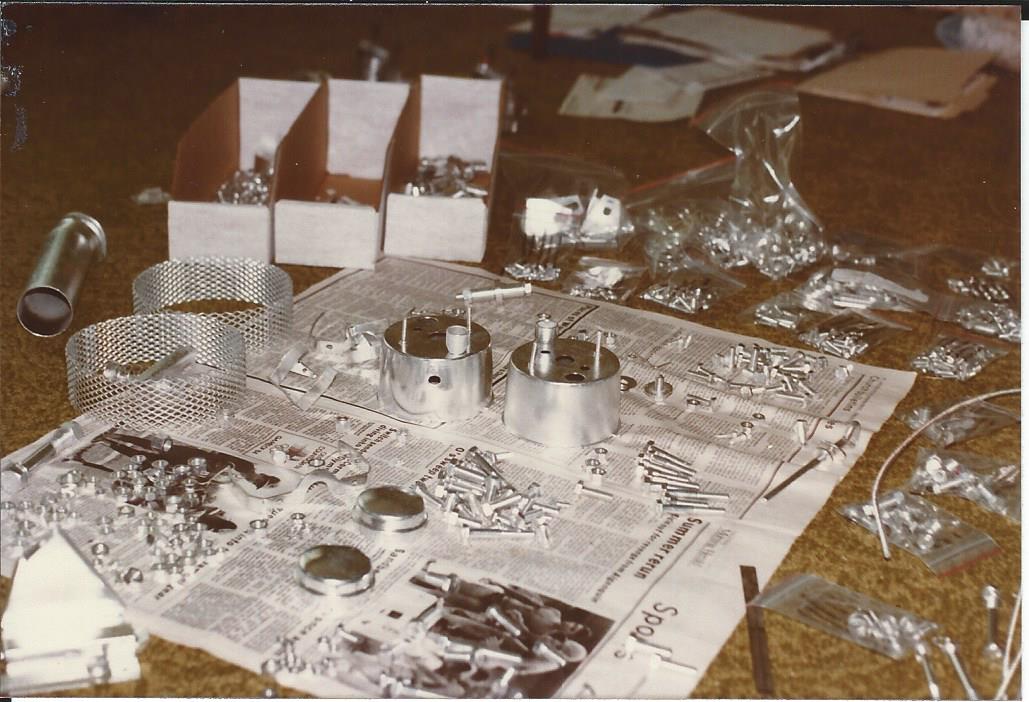

I believe the original plating was cadmium. We have all bought bolts from the hardware store,those are zinc and you see how long the finish lasts. You've all seen bolts that look yellow,that is called trivalent yellow chromate it is used to further protect the zinc. It comes in clear as well. It is needed because zinc does not last as long as cadmium. Cadmium is not used as much as it was due to EPA regulations,it's nasty stuff to work with and to dispose of much like chrome.Can still be found but not as cheap as it once was. Here is some cadmium plating I had done in the 80's.As you can see it is very bright. At the time it was a dollar a pound- 50 lb minimum. I just sold the car last year after 37 years. The finish had dulled some but not bad.

Here in contrast is some parts I recently had done in zinc with a trivalent yellow chromate finish -

Here in contrast is some parts I recently had done in zinc with a trivalent yellow chromate finish -

JHminitrails

Well-Known Member

Here are some parts of mine fresh out of the vibratory tumbler with green abrasive pyramids and 50/50 mix of CLR and water. Pic is attached off what they looked like before. I ran the tumbler for about 20 hours. Only because I didn't have time in the morning to remove them. But I checked them after 10 hours run time, and they were already spotless, they could have easily been removed at that point, but I didn't have time.

I remove them then rinse them in a strong solution of baking soda and water, then blow dry with compressed air and bag them up immediately. Then off to plating.

I remove them then rinse them in a strong solution of baking soda and water, then blow dry with compressed air and bag them up immediately. Then off to plating.

Looks good! I have the same tumbler and medium. I have been plating my zinc plating my own stuff although it come out of plating with a dull gray finish. I think have to take steel wool to it. It is an easy process but not when it comes to parts like the seat latch. It is almost impossible to get into all the little areas.

JHminitrails

Well-Known Member

Looks good! I have the same tumbler and medium. I have been plating my zinc plating my own stuff although it come out of plating with a dull gray finish. I think have to take steel wool to it. It is an easy process but not when it comes to parts like the seat latch. It is almost impossible to get into all the little areas.

Thanks! I'm very happy with the results. The seat latch will actually come apart fairly easily, you just have to knock the pin out that locks the catch tab to the lever shaft. I've done it in the past and worked well. I didn't bother with the last 2 seat latches as they were quite clean, just dull from age, but no rust.